Filtration Group

Spray Booth Pre & Exhaust Bag Filter

Spray Booth Pre & Exhaust Bag Filter

Regular price

$167.75 USD

Regular price

Sale price

$167.75 USD

Unit price

per

Shipping calculated at checkout.

Couldn't load pickup availability

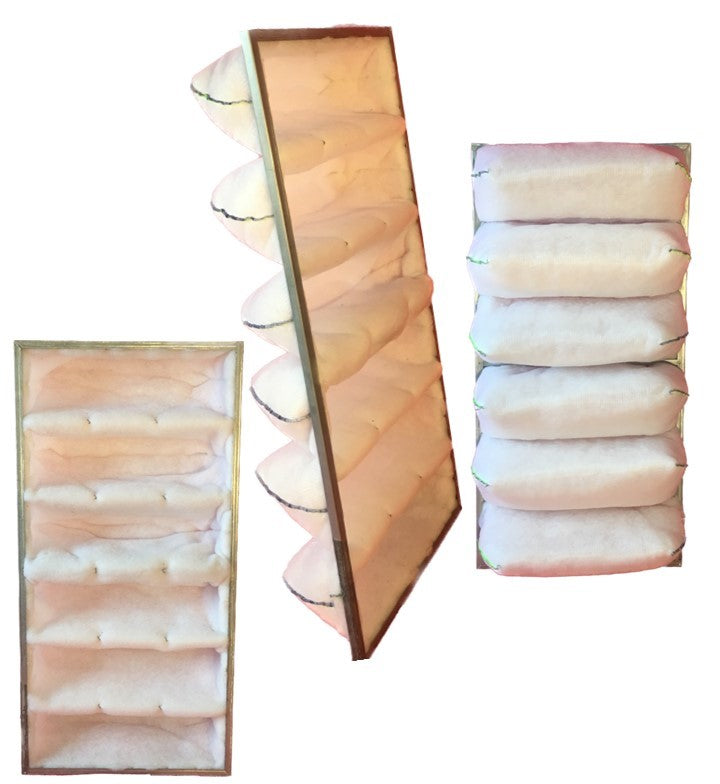

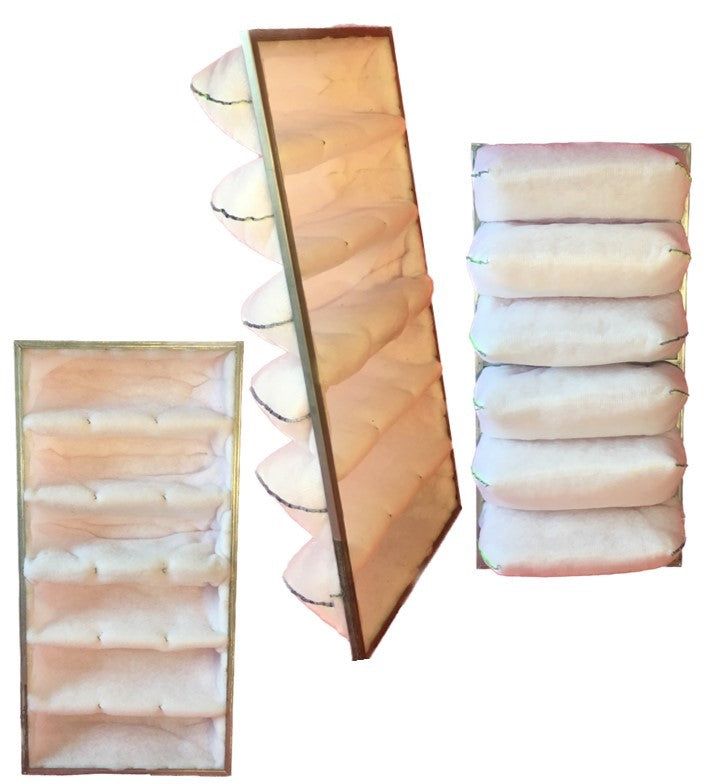

Designed for high-demand spray booth environments, our pocket pre-filters and exhaust filters offer exceptional durability and efficiency. Internally supported and constructed from scrim-backed fiber or high-capacity dual-density fiber, these filters provide reliable performance and extended service life.

The pocket and cube configurations expand the filter surface area, increasing paint-holding capacity and allowing for longer intervals between replacements. This design optimizes airflow and ensures consistent filtration in automotive, aerospace, and industrial painting applications.

Custom Filters

Don't see the size you need? Our custom filters can be fabricated to fit any application!